Innovation

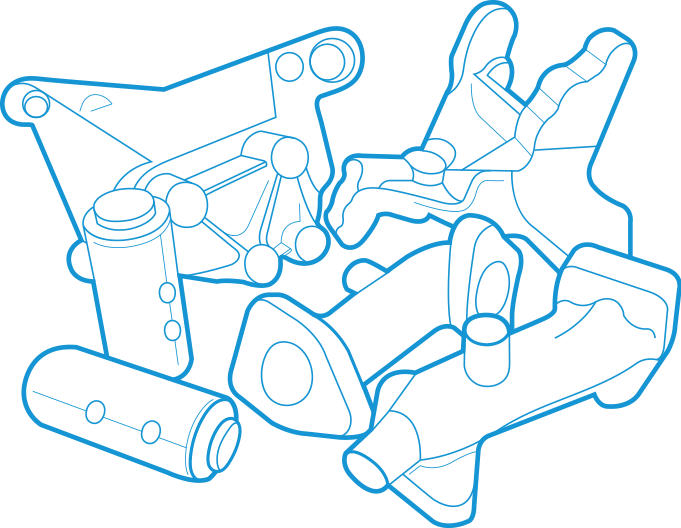

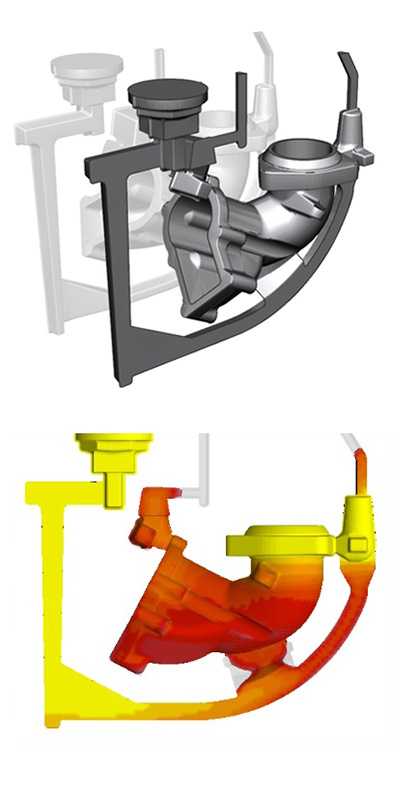

Time to market has become crucial in today business. We put effort at the very beginning of product life cycle. Pattern, Die and gating system are designed in 3D model (CAD) by advanced tool as NX9.0. In addition, casting simulation is approached to help us to understand liquid metal behavior from flowing into the mold until transforming to be solid.

These powerful tools enhance opportunities to improve casting yield and predict defects such as pinhole, shrinkage, etc. Quality and productivity issues can be solved in less time and with lower costs by evaluating alternative concepts with simulation before pattern or die are released to production. This results to dramatically reduce the numbers of trial and error. Product can be launched in mass production faster

In addition, these advanced tools enhance simultaneously working among customer, the company and also pattern maker at the beginning of the design process.

Rapid prototype technology is also approached in our design process.

– Providing more alternatives for customers -

– Providing more alternatives for customers -

By 3D sand printing technology, the problem of producing less number of casting and the need for pattern making can be eliminated. The prototype can be made in less number, shorter time and lower cost without pattern required.