core

process

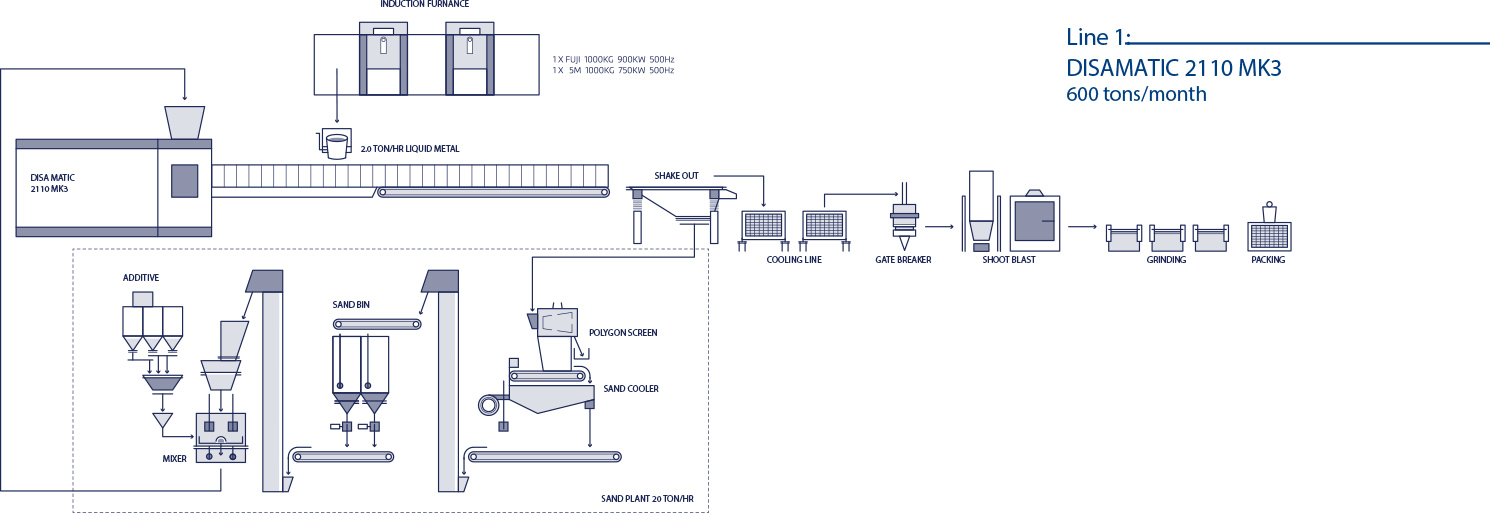

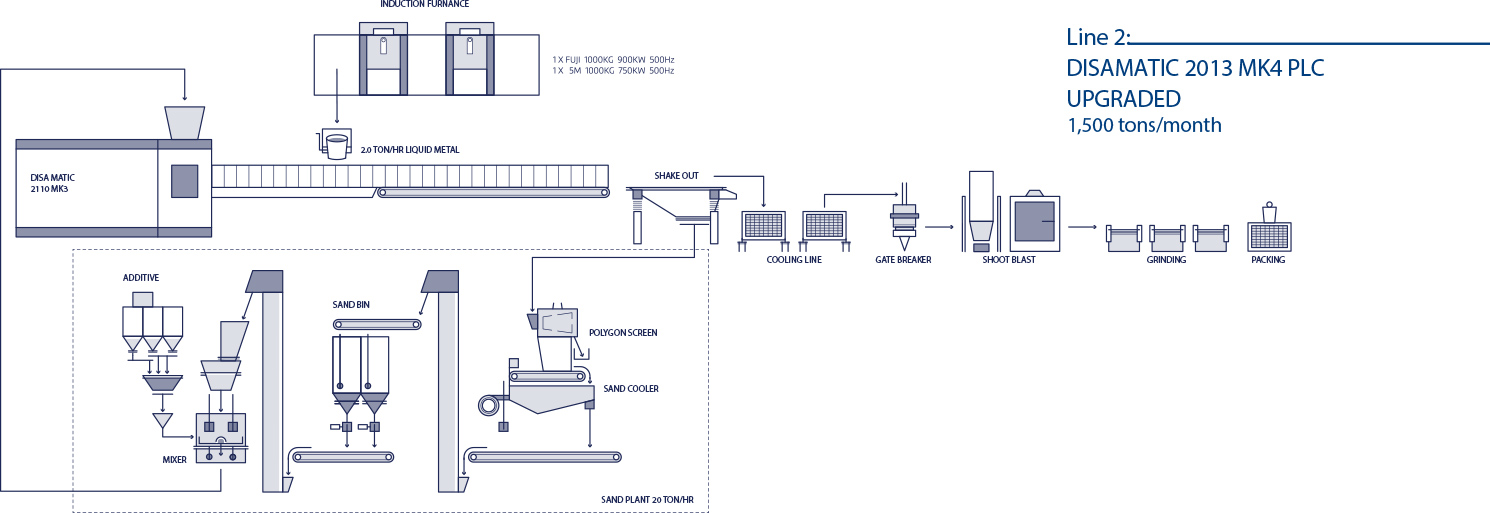

Two production line are the key process driving the company. Generally, casting process consists of 3 main processes, which are melting & pouring, molding & core, and finishing process, - including de-gating, shot blasting, grinding and packing process.

Similar to our production line, as the figure below, the first line is equipped by 1 Ton x 2 induction furnaces and DISAMATIC 2110 MK3 including sand plant. This line can produce liquid metal 2 ton/hr.

Similar to our production line, as the figure below, the first line is equipped by 1 Ton x 2 induction furnaces and DISAMATIC 2110 MK3 including sand plant. This line can produce liquid metal 2 ton/hr.

The second line, which has 2 – 2.5 times capacity by the first one, is equipped by 3 Ton x 2 induction furnace (melt & hold) and DISAMATIC 2013 MK4 PLC UPGRADED including sand plant. 4.5 ton/hr. liquid metal can be produced by this line. The details and capacity of each process are shown in table 1.1.